Step by step to a better quality of life

STOBER continues to improve predictive maintenance.

Greater efficiency, fewer breakdowns – with these goals in mind, STOBER continues to enhance its predictive maintenance. The drive specialists have also defined several expansion stages: they continuously monitor the drive train and derive maintenance recommendations based on the analysis of the relevant process and machine data. The possibilities range from analytical calculation models to AI-supported processes. STOBER is following an integrated solution strategy. This requires no external sensors or accessories and is accessible for a wide range of controllers.

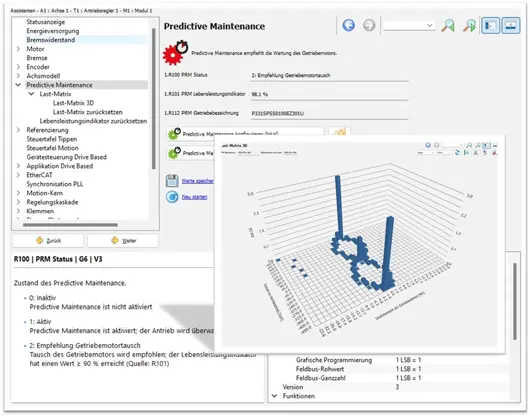

“How can we use predictive maintenance to make the transition from pure condition monitoring to real condition-based servicing for drive trains?” Tim Lang, Head of System & Test at STOBER, and his team asked themselves. Predictability is becoming increasingly important for users who want to achieve higher availability, lower maintenance costs and longer life cycles. “How likely is it that the geared motor will fail soon?” or “When is the ideal time to service or replace it?” To answer these questions, STOBER is pursuing a three-stage development plan, the second stage of which is currently being implemented.

First stage: model-based analysis

In the first expansion stage, users received a predictive maintenance solution that monitors the geared motor of a drive system. Its life performance is calculated using an analytical model and then output in the drive controller software via a life performance indicator, which is a value between 0 and 100 percent. At a threshold value of 90 percent or above, the software recommends replacing the geared motor and also makes this information available to a controller in the form of a readable parameter. This efficient solution for predictive maintenance requires neither external sensors nor additional wiring.

Second stage: active measurement

“In the second stage, the calculation model is supplemented by active measurement,” explains Tim Lang. For this purpose, STOBER is integrating an acceleration sensor into its system consisting of a gearbox, motor, cable and drive controller. External power and voltage sources are not required. This approach allows targeted monitoring of bearing seats, toothing and other drive components. “Frequency analyses enable us to draw conclusions about impending damage based on a spectrum,” said Lang. “Right now, we are still in the prototype phase.” STOBER is working closely with DR. JOHANNES HEIDENHAIN GmbH to develop a geared motor with an integrated acceleration sensor.

The goal in sight: a smart drive train

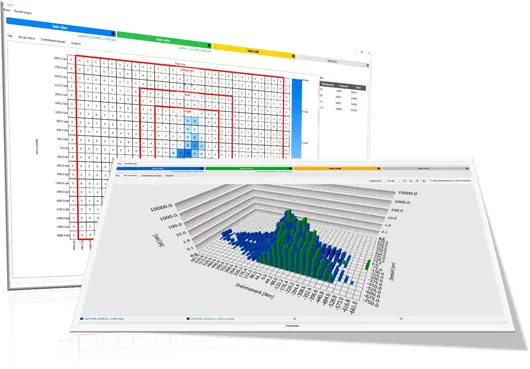

“Among other things, we have improved the analytical model and expanded the database to over 80,000 combinations of gearboxes and motors,” says Tim Lang. With the new LoadMatrixAnalyzer, which will be available in the coming months, customers will be able to compare load matrices even more easily, generate standardized reports and create individual evaluations on request. Users benefit from easier operation and improved visualization. In the future, STOBER will also provide function blocks and sample programs with which the data obtained – in particular the load matrices – can also be read out via EtherCAT or PROFINET.

For the LoadMatrixAnalyzer, the load matrices form a solid database for recording real load situations. This opens up a wide range of applications for condition-based servicing, from the detection of design and assembly influences to meaningful long-term analyses.

Tim Lang: “Users assign a project name for each analysis of the load matrices. This allows individual matrices to be clearly named, described and provided with all relevant information for the analysis report. The LoadMatrixAnalyzer itself offers several central functions. These include the representation of load cases. Here, torque and speed at the gearbox output are visualized over time in a 3D diagram, making load situations visible at a glance.”

In addition, the standard limits for the motor, gearbox and drive controller can be displayed individually or in combination. This makes it immediately apparent whether certain load ranges are within the permissible value ranges or whether deviations occur that need to be examined more closely and evaluated individually.

Finally, the results can be documented directly in the Analyzer. This determines whether the load is a non-critical momentary load or whether there are potential risks for individual components.

The LoadMatrixAnalyzer can also be used to compare up to four load matrices with one another. This makes it clear how the speed and torque have changed over a certain period of time. “This shows us, for example, whether a gearbox has already run in or whether there are signs of stress and defects,” explains STOBER expert Lang. The analyses can then be exported as a standardized report in PDF format.

Tim Lang: “For me, the tool is more than just an auxiliary program – it’s a stand-alone piece of software. It can be updated, and we are continuously developing it further.” In the next steps, STOBER will expand its predictive maintenance solutions with AI support. The aim is a smart drive train that can both recognize its own condition and provide relevant field data in real time.

Captions:

Photo credits: STÖBER Antriebstechnik GmbH + Co. KG

You can find high-resolution image material to download here.

STOBER develops and produces precise, highly efficient drive components and systems, including gearboxes, motors, gear racks and drive controllers for custom solutions. They are used in various industries, including automation and robotics, as well as the plastics, packaging and machine tool industries. STOBER has 14 locations and 80 service partners in over 40 countries. In addition to its headquarters in Pforzheim, Germany, there are also production facilities in Hungary and the US. The family-owned company currently employs around 1,000 people worldwide.

Contact data for country-specific publication:

| Germany: | Austria: |

| STÖBER Antriebstechnik GmbH + Co. KG Kieselbronner Str. 12 75177 Pforzheim Phone: +49 7231 582-0 sales@stoeber.de www.stober.com | STÖBER Antriebstechnik GmbH Hauptstraße 41a 4663 Laakirchen Phone: +43 7613 7600-0 sales@stoeber.at www.stoeber.at |

| Switzerland: | |

| STÖBER Schweiz AG Rugghölzli 2 5453 Remetschwil Phone: +41 56 496 9650 sales@stoeber.ch www.stober.ch |

Press contact:

STÖBER Antriebstechnik GmbH + Co. KG

Silvia Feder│Head of Marketing

Kieselbronner Str. 12

75177 Pforzheim│Germany

Phone: +49 7231 582-1660

silvia.feder@stoeber.de

www.stoeber.de/en/

Media:

STÖBER Antriebstechnik GmbH + Co. KG

Solveig Moll

Kieselbronner Str. 12

75177 Pforzheim│Germany

Fon: +49 7231 582-1183

solveig.moll@stoeber.de

www.stoeber.de/en/

Please send a specimen copy to our agency:

a1kommunikation Schweizer GmbH

Sarah Grujin

Project Management │ Client Support

Oberdorfstr. 31A

70794 Filderstadt│Germany

Phone: +49 711 945 416-27

Sarah.Grujin@a1kommunikation.de

www.a1kommunikation.de