From another Point of View

STOBER presented the new generation of its servo planetary geared motors at the SPS IPC Drive in Nuremberg at the end of 2019.

One of the special features of this generation: Each motor series can be directly mounted in any available size. With this variance, STOBER offers ready-to-install drive solutions for machine tools and packaging machines as well as applications in automation and robotics. In order to ensure that the assembly of the new gearboxes remains efficient even with an increased variety of combinations, the specialist from Pforzheim relied “on digital” when planning the new production line and gained new perspectives through virtual reality.

With the third generation of its servo geared motors, STOBER has developed high-performance and precise drive solutions that are the most compact on the market in terms of versatility and convince by their enormous variance. The gearboxes can not only be combined with different STOBER motors in direct mounting, but also with all third-party motors of any size via a one-of-a-kind interface technology. A perfect fit for any application.

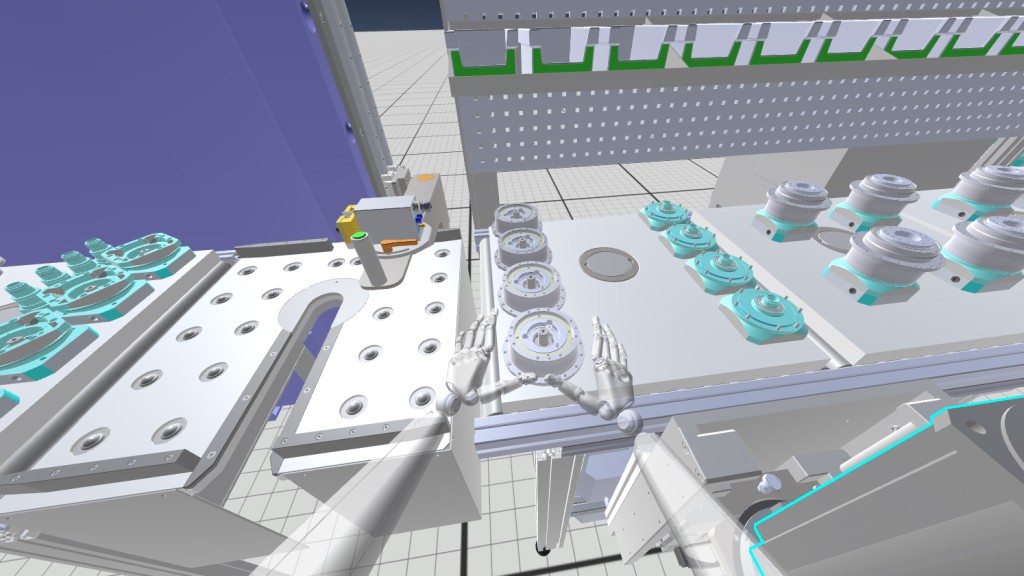

During the development of the new drives, the STOBER design engineers faced a wide range of challenges: Compared to the previous version, for example, the performance had to be improved and the components had to be built significantly more compact – at the same cost. A balancing act which STOBER mastered primarily by means of new production technologies and optimized assembly lines. “Especially the work and assembly planning, not to forget the optimization of the ergonomics at each of our workplaces, is one of the most important, but unfortunately also one of the most time-consuming tasks”, says Marc Schneider, team leader in gear assembly at STOBER. “Instead of building physical prototypes on the basis of our CAD or Excel data and modifying them again and again, we relied on virtual reality for the design and optimization of the assembly lines in advance”.

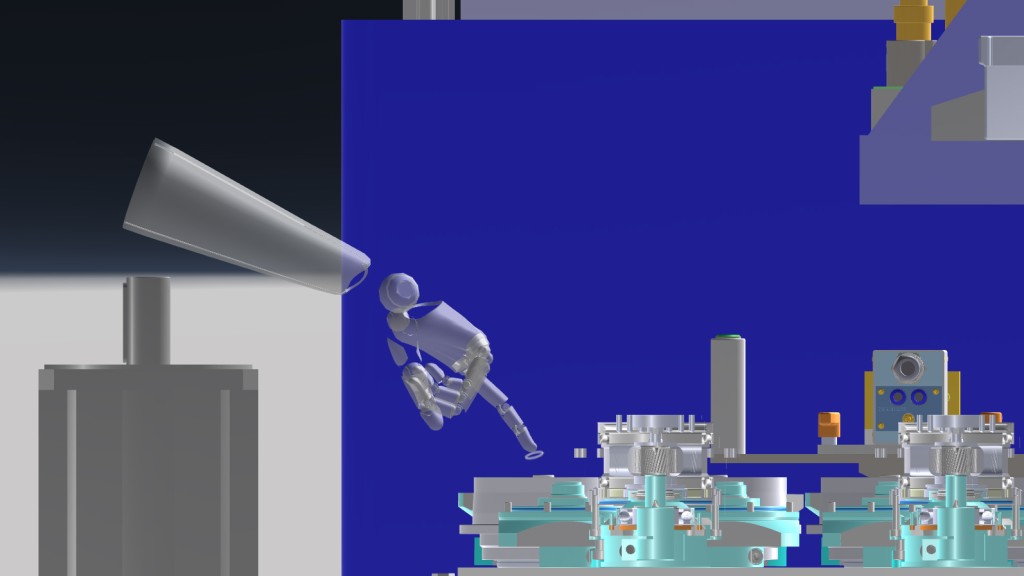

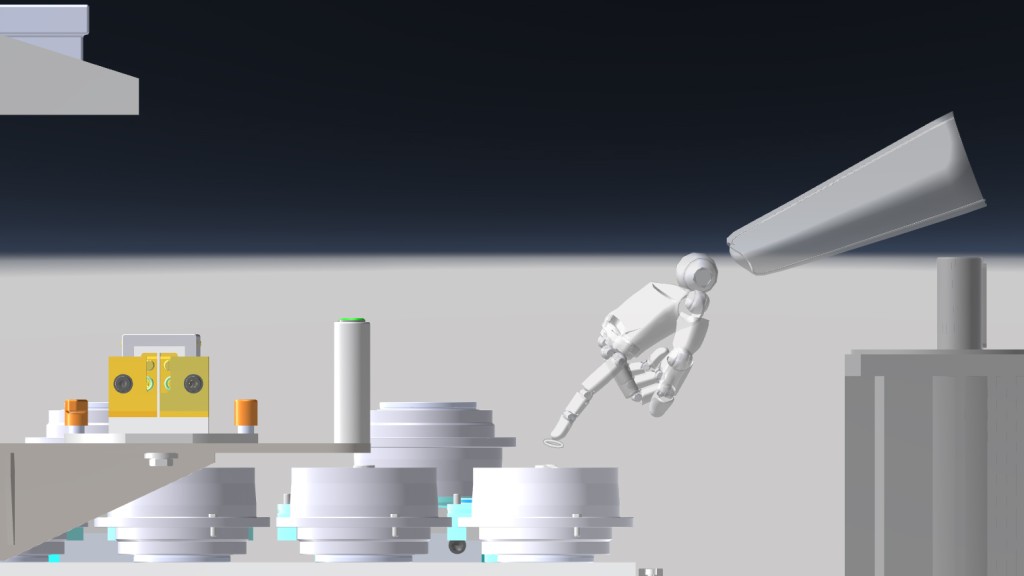

With a VR tool by R3DT, a start-up based in Karlsruhe which STOBER chose, entire systems can be simulated as early as the conception phase. By means of VR glasses environments can be experienced one-to-one. A “simple” principle with great effect: 3D CAD data from workstations, for example, are imported into the VR software along with other relevant key figures and processed. At the push of a button virtual prototypes are ready to be used.

“VR glasses on and we are already standing in the virtual environment at the previously designed workstations. With our hands we can reach for virtual tools, check the screwing – without joysticks or other controllers”, Schneider explains.

Frequent testing allows design errors to be detected in good time; corrections in the design or even in the ergonomics of a workstation can be made directly – even in the early planning phase. For STOBER numerous aspects that needed improvement came to light before real prototypes were built.

The resulting real prototypes are very close to being ready for production. In addition to saving an enormous amount of time and avoiding costly subsequent modifications, Marc Schneider is pleased to be able to involve his co-workers right from the start.

“We are very motivated to make our everyday work more ergonomic. Another advantage is that the VR tool gives the entire team the opportunity to experience and learn about new technologies in early stages. In addition, we can now react more effectively in assembly to the ever-changing product mix that our customer requires. An exciting project!”

Captions:

Photo credits: STÖBER Antriebstechnik GmbH + Co. KG

Media contact, editorial / market overviews:

Please note the new persons responsible for PR & media:

STÖBER Antriebstechnik GmbH + Co. KG

Silvia Feder

Kieselbronner Str. 12

75177 Pforzheim │ Germany

Fon: +49 7231 582-1660

silvia.feder@stoeber.de

www.stoeber.de

Media:

STÖBER Antriebstechnik GmbH + Co. KG

Solveig Moll

Kieselbronner Str. 12

75177 Pforzheim │ Germany

Fon: +49 7231 582-1183

solveig.moll@stoeber.de

www.stoeber.de

Please send a specimen copy to our agency:

a1kommunikation Schweizer GmbH

Sarah Hartung

Project Management│Client Support

Oberdorfstr. 31A

70794 Filderstadt│Germany

Fon: +49 711 945 416-27

eva.neubert@a1kommunikation.de

www.a1kommunikation.de

Contact data for country-specific publication:

Germany:

STÖBER Antriebstechnik GmbH + Co. KG

Kieselbronner Str. 12

75177 Pforzheim

Fon: +49 7231 582-0

sales@stoeber.de

www.stoeber.de

Austria:

STÖBER Antriebstechnik GmbH

Hauptstraße 41a

4663 Laakirchen

Fon: +43 7613 7600-0

sales@stoeber.at

www.stoeber.at