Precision gear racks – optimize your choice

For optimum feed force transmission: flexible, safe, efficient.

Tradition meets high-tech

Did you know that gear racks were originally used to place objects at different heights — for example, to position pots at the best height above a fire?

As the industrial revolution took hold, the gear rack became an essential machine element, and it would be impossible to imagine modern mechanical engineering without it today.

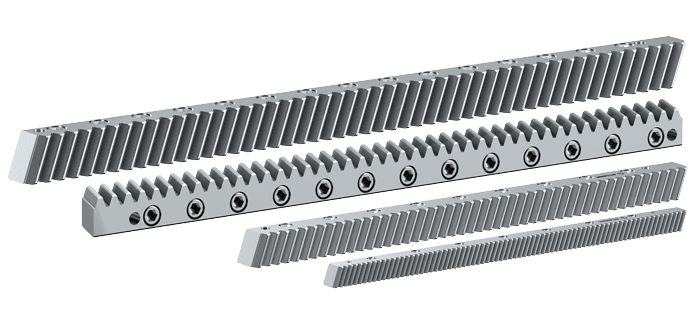

STOBER offers precision gear racks in various lengths to ensure that you find the perfect solution for every design task – and is now adding a 2-meter version to the range. This can be seamlessly combined with the proven 0.5- and 1-meter versions to create individual, custom-fit solutions.

STOBER is expanding its gear rack portfolio to include 2-m gear racks.

The right choice for your application:

- 0.5 meters and 1 meter – with double the number of bores

Twice the number of bores with a spacing of just 62.5 millimeters ensures increased contact pressure and generally eliminates the need for pinning. However, if required, this option is still available. If every second bore is used, the gear racks are fully compatible with standard commercially available systems. - 2 meters – for long travel paths

Perfect when it comes to efficiency and precision over long distances: fewer mounting points, minimal impact points and reduced pitch deviations. As usual, it is reliably fastened by the screws, while pinning is still possible as an option.

It’s your choice!

Find the perfect gear rack for your application.

- Short and flexible – with twice the bores and maximum compatibility

- Long and efficient – for maximum precision with long travel paths

The benefits at a glance.

- Optimum power transmission for every application

- Flexible choice between compact (0.5 m / 1 m) or long versions (2 m)

- Optional pinning for additional safety

- Reduced installation time and maximum precision

- All variants are compatible with each other

Figures. Data. Facts.

Our precision gear racks are available in various lengths and modules, for the highest demands on smooth operation and positioning accuracy.

- Module: 2 – 8 mm

- Max. feed force: 1.3 – 124 kN

- Helical, hardened, and smoothed

- Gearing quality 6 in accordance with DIN 3962-1

- Length: 0.5 m, 1 m, 2 m

“With length variants of 0.5, 1 and 2 meters, we offer a portfolio that gives our customers even more freedom to design their drives efficiently and precisely.”

– Matthias Eberle, Director Business Development Asia Pacific bei STÖBER

“With length variants of 0.5, 1 and 2 meters, we offer a portfolio that gives our customers even more freedom to design their drives efficiently and precisely.”

– Matthias Eberle, Director of Business Development Asia Pacific at STOBER

Consistent system concept.

From high flexibility to high force: Our innovative concept for rack and pinion gearboxes, combined with planetary or helical bevel gear units and directly mounted servo motors, offers a perfectly coordinated system that can be flexibly adapted to a wide range of requirements in terms of load capacity and precision. It is ideal for applications in machine tools or automation and robotics.

We are happy to help.

This might also interest you

With the innovative system concept for rack and pinion gearboxes, STOBER has developed a compact, easy-to-use system with process reliability – ideal for automation & robotics.

Rack and Pinion Gearboxes with Synchronous Servo Motors

From full rotation to linear: Innovative rack and pinion gearboxes with synchronous servo motors from STOBER for ultra-compact, highly dynamic drive solutions.

Hot topics such as energy efficiency and eco-design are highly relevant at STOBER.

The new hybrid cable connects motors and drive controllers reliably up to 100 meters.