Mastering Complexity with Ease

Mechanical and design engineers are always pressed for time.

Putting together just the right drive solutions is particularly time-consuming ─ especially if you have to gather and compare extensive manufacturer-specific documentation. STÖBER Antriebstechnik analyzed this time-waster and presented the new STOBER product configurator, at Hannover Messe. Thanks to the cutting-edge design and simple navigation, the user can navigate in the online tool intuitively and design individual solutions quickly in real time with just a few clicks.

Numerous filters and comparison options are available to them for this purpose. Then, the user can download the 2D drawings, 3D models or data sheet for the selected products and request a quote directly. The finished selection can also be saved for later use and shared with others.

STOBER is focused on providing even more comprehensive support for customers through digital services. To make ordering replacement parts easier, for example, the drive specialist equips all components with nameplates that contain a QR code. The user can scan the code with a smartphone or tablet and immediately receive all the important information about the corresponding module, such as operating and assembly instructions, replacement part lists or information on technical features. This practically eliminates the possibility of mixing up replacement parts, which is often only noticed during installation. Service technicians are also able to call up the information without needing to involve the machine manufacturer. And thanks to this fast, direct access to all data, the effort needed for storage is significantly reduced.

The drive specialist showed off its automation strength at the exhibition booth using an individual SCARA robot whose axes were controlled centrally by the STOBER MC6 motion controller with EtherCat. The independent drive and motion control architecture can handle complex mechanical systems reliably and powerfully.

Cooperation with Pilz GmbH & Co. KG

In the area of safety technology, STOBER has been working with Pilz GmbH & Co. KG for many years with great success. In Hannover, the drive specialist exhibited a model with a spindle motor and connected synchronous servo motor with hollow shaft equipped with a light barrier and laser scanner to demonstrate flexible, safety-oriented machine protection. If the user enters the designated hazard zone in front of the machine, the velocity of the axes is reduced and monitored safely (Safely-Limited Speed; SLS). If the user reaches into the area of the axis protected by the light barrier, the drives shut down in a controlled manner and the safe stop is monitored (Safe Stop 2; SS2). If one of the drive axes moves during active stop monitoring (Safe Operating Stop; SOS), the “Safe Stop 1” (SS1) stop function is activated inside the drive. The drive shuts down immediately in a controlled manner and then interrupts the energy supply to the motor (Safe Torque Off; STO). In doing so, all safety functions used reach SIL 3/ PL e/ category 4, regardless of the motor encoder systems used.

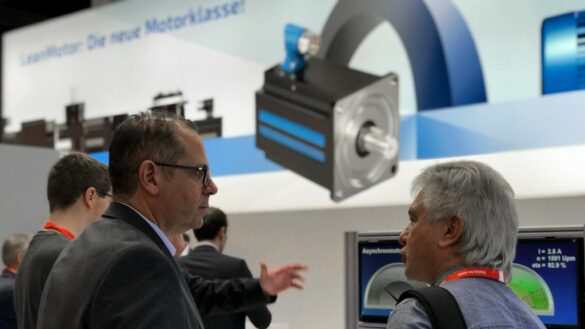

Visitors were also able to learn about the sensorless Lean Motor at the exhibition booth. This new development is significantly lighter and smaller than an asynchronous drive with the same output and is more cost-efficient and more rugged than a servo drive. With up to 96 percent efficiency, the STOBER Lean Motor corresponds to the IE5 energy efficiency class. As a result, engineers are able to design more compact, future-proof machines and users benefit from lower energy consumption and a long service life. For example, the new motor class can be used for dynamic automation tasks in harsh production environments. STOBER presented an exciting example at the exhibition booth.

Captions:

Photo credits: STÖBER Antriebstechnik GmbH + Co. KG

Media contact, editorial / market overviews:

Please note the new persons responsible for PR & media:

STÖBER Antriebstechnik GmbH + Co. KG

Silvia Feder

Kieselbronner Str. 12

75177 Pforzheim │ Germany

Fon: +49 7231 582-1660

silvia.feder@stoeber.de

www.stoeber.de

Media:

STÖBER Antriebstechnik GmbH + Co. KG

Solveig Moll

Kieselbronner Str. 12

75177 Pforzheim │ Germany

Fon: +49 7231 582-1183

solveig.moll@stoeber.de

www.stoeber.de

Please send a specimen copy to our agency:

a1kommunikation Schweizer GmbH

Sarah Hartung

Project Management│Client Support

Oberdorfstr. 31A

70794 Filderstadt│Germany

Fon: +49 711 945 416-27

eva.neubert@a1kommunikation.de

www.a1kommunikation.de

Contact data for country-specific publication:

Germany:

STÖBER Antriebstechnik GmbH + Co. KG

Kieselbronner Str. 12

75177 Pforzheim

Fon: +49 7231 582-0

sales@stoeber.de

www.stoeber.de

Austria:

STÖBER Antriebstechnik GmbH

Hauptstraße 41a

4663 Laakirchen

Fon: +43 7613 7600-0

sales@stoeber.at

www.stoeber.at