Precision in size XL

STOBER develops fourth generation of its large planetary gearboxes.

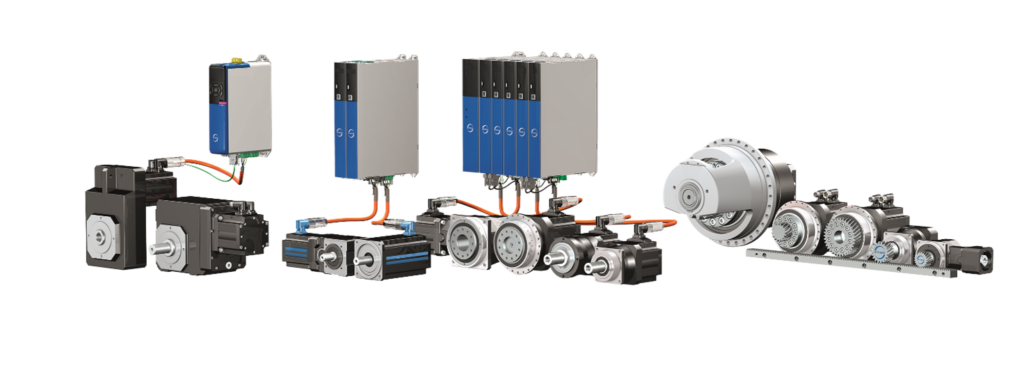

With the fourth generation of the PH series, STOBER presents extremely precise servo planetary gearboxes that are the largest on the market in their performance class. In addition to their high precision, these are also energy-efficient. STOBER also offers the variant as a geared motor.

Planetary gearboxes are the premier class of gearboxes. STÖBER Antriebstechnik GmbH + Co. KG has been one of the specialists in this area for almost 40 years. These components have a compact design and can transfer high torques because the forces are distributed across multiple gears, unlike conventional gearboxes. With the current planetary gearboxes, the drive specialist is now launching the fourth generation of the large sizes. These can be combined with the compact synchronous servo motors of the EZ series and mounted directly. Without an adapter, the mass moment of inertia is lower and the drive is more dynamic. With STOBER motor adapters, the drive specialist can connect all suitable third-party motors to the gearbox series. For this purpose, the adapters are available with different couplings as well as with an integrated brake in the ServoStop variant. With the extra-large motor plate in the Large version, the user can mount motors with a very large design. If desired, the PH gearboxes are also available with a driving angle stage.

STOBER designed the fourth generation of its PH gearboxes to be up to 100 millimeters shorter than the previous version. This has a positive effect on the rigidity and mass inertia. The new gearboxes also require less installation space, are lighter and in some cases offer around 20 percent more torque – as well as a 50 percent increase in tilting torque.

The excellent housing and gearing quality increases the acceleration torque by up to eleven percent and also increase the running accuracy and precision. In addition, there is a very high tilting stiffness. STOBER has increased parameters such as power density and torsional stiffness, and has widened or more generously dimensioned the planetary gears for certain gear ratios. State-of-the-art materials and hardening processes are also used for the planetary gears and sun pinions, as well as lifetime lubrication with synthetic gear oil. Since this makes the new gearbox series extremely stable and robust, service and repairs become virtually unnecessary.

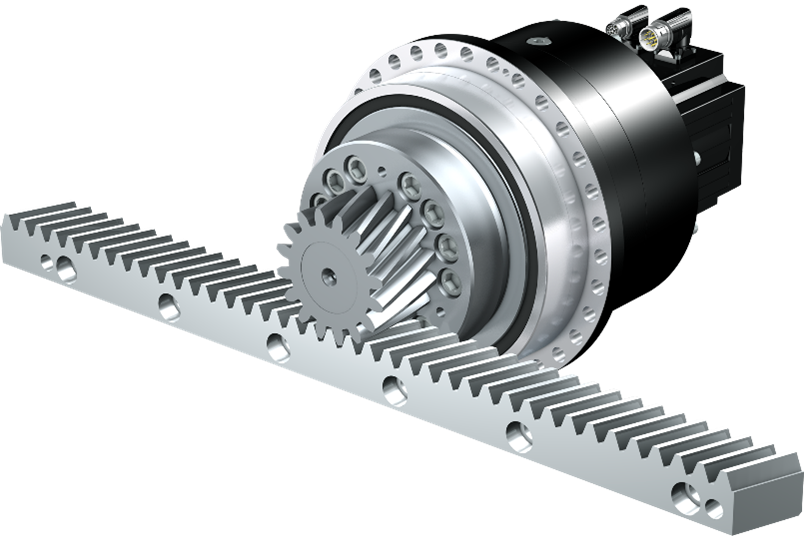

With a ratio range of 12 to 600, the new PH gearboxes are particularly flexible in use. In addition to the standard PH version, STOBER also has a Quattro design in its range. The PHQ series with a four-planet system is also extremely precise with its high-quality helical gearing and offers even greater torsional stiffness. The user also benefits from maximum torque. On request, STOBER also combines the fourth generation with rack and pinion drives of the ZTR and ZTRS series. This gives the user high-performance geared motors, such as for use in feed axes of machine tools. Due to their high efficiency, the new planetary gearboxes are in demand wherever size, precision, economy and efficiency play a role.

The drive specialists have also optimized the design of the new generation and adapted it to the family of STOBER planetary gearboxes.

Pictures

Contact data for country-specific publication:

Germany

STÖBER Antriebstechnik GmbH + Co. KG

Kieselbronner Str. 12

75177 Pforzheim, Germany

Phone: +49 7231 582-0

sales@stoeber.de

www.stober.com

Austria:

STÖBER Antriebstechnik GmbH

Hauptstrasse 41a

4663 Laakirchen, Austria

Phone: +43 7613 7600-0

sales@stoeber.at

www.stoeber.at

Please note the new persons responsible for PR & media:

Media contact, editorial / market overviews (NEW):

STÖBER Antriebstechnik GmbH + Co. KG

Silvia Feder

Kieselbronner Str. 12

75177 Pforzheim │ Germany

Phone: +49 7231 582-1660

silvia.feder@stoeber.de

www.stoeber.de/en/

Media:

STÖBER Antriebstechnik GmbH + Co. KG

Solveig Moll

Kieselbronner Str. 12

Phone: +49 7231 582-1183

solveig.moll@stoeber.de

www.stoeber.de/en/

Please send a specimen copy to our agency:

a1kommunikation Schweizer GmbH

Sarah Hartung

Project Management│Client Support

Oberdorfstr. 31A

70794 Filderstadt │ Germany

Phone: +49 711 945 416-27

eva.neubert@a1kommunikation.de

www.a1kommunikation.de