BOSCHERT relies on drive technology from STOBER for its copper punching machine.

The CuMaster from BOSCHERT is a highly dynamic, high-precision copper punching machine that processes long copper, aluminum and steel bars. The machine manufacturer relies on right-angle planetary gear units, right-angle servo gear units and inline and offset gear units from STOBER, as well as on the drive specialist’s new rack and pinion drive. Compared to the previously installed spindle drives, these components are considerably more flexible, more compact, faster and more dynamic, which adds to the system’s competitive edge. Critical factors for the collaboration were quality, the good price-performance ratio and a wide portfolio from a single source.

Standing up to competitive pressure

The requirements of our customers have risen significantly,” says Manuel Kunzelmann, design engineer at BOSCHERT. It is a fact he has known for some time. “They not only expect long-lasting machines of high quality. High performance at a low price is also becoming more important.” The systems are also becoming more complex, as they have to offer more and more options. BOSCHERT consistently adapts its machines to the challenges of the customers. But as Kunzelmann says, “Due to increasing competitive pressure, we have less and less time available to do so.”

In Lörrach, deep in Germany’s southern Black Forest, BOSCHERT GmbH employs 125 employees and produces punching machines that are used by sheet metal processors and control cabinet manufacturers, among others. The Baden-based company is active worldwide: Systems are sold successfully in Europe as well as in Asia and the USA.

The CuMaster is one of the latest developments. “This copper punching machine is suitable for material dimensions up to 310 × 20 × 6,000 millimeters,” says Kunzelmann. “The highly dynamic, flexible series is used for processing predominantly copper, but also aluminum and steel bars, such as for bus bars in transformer construction, solar energy production or in wind turbines – in other words, when high currents need to be transmitted.” The development of this system started back in 2020, and the first prototype was delivered in early 2024. “To date, we have sold 15 machines,” says Kunzelmann. “It’s a wonderful result that gives us a good basic utilization rate in the current difficult economic situation.”

Embodying quality together

BOSCHERT cannot produce everything in-house. Therefore, the machine manufacturer relies on selected suppliers. “It is important for us that they work along with us as partners and embody quality just as we do,” Kunzelmann explains. Suppliers come from Europe, and of course right nearby in Germany, such as the drive specialist STOBER, which is just under 160 kilometers away from Lörrach in Pforzheim. “The CuMaster is our first project together,” says Alexander Schmidt, Area Sales Manager at STOBER. “I knew BOSCHERT from my previous job. I’ve encountered them many times since. When I learned of this project, I got in contact.” The machine manufacturer was aware of the high quality of the components, the technical expertise of the drive specialist and, above all, the excellent price-performance ratio. “It is also relevant for us that STOBER can deliver everything from a single source,” Kunzelmann emphasizes.

The CuMaster is characterized by high velocity and dynamics with precise functioning. This is what makes the punching machine so competitive. With its enormous selection of tools, users have countless options. “The machine has a total of eight tool stations,” says Kunzelmann. “One-way, three-way and eight-way tools are available.” There is a station in the tool carrier with which copper components up to 200 × 20 millimeters can be cut in one pass. The punching head can apply either 22 tons in slow mode or 60 tons in fast mode to the workpiece. For forming processes such as beading or deep drawing, BOSCHERT equips the machine with up to three lowerable hydraulic dies. Dynamic collets guide the material through the system. “We used to use spindle drives for axis positioning,” says Kunzelmann. But they did not allow the design engineers to be flexible, as the installation of these components depended on the length. They also required a lot of maintenance. What’s more, they weren’t compact enough for the CuMaster. “We supplied our new rack and pinion gearboxes for this task,” says Schmidt. “We offer them in various series, in a modular version and with numerous lengths. They allow us to approach specific applications individually.”

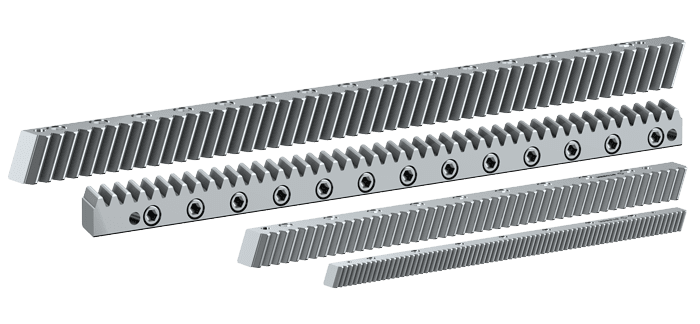

Easy-to-install gear racks

The special thing about the new rack and pinion gearboxes is that pinning is optional. A gear rack must not move when force is applied by the pinion. Competitors usually ensure this by using dowel pins at both ends of the gear rack in addition to the pressing force provided by the screw fastenings. However, the bores for the dowel pins must be made and then reworked with a reamer directly on the machine in the bolted-on state. “Especially for complex systems with many attachment parts like the CuMaster, this work is extremely laborious and time-consuming,” Schmidt says. “We delivered our precision gear racks with twice the number of bores. There is a bore for a screw connection every 62.5 millimeters, instead of every 125 as usual.” This doubles the contact pressure of the component on the machine body. At the same time, this also makes it extremely easy to install.

“The ZR series features large, helical pinions with a bolt circle. This enables high feed velocities,” Schmidt says. And since the pinions are mounted without an additional flange, this is reflected in the attractive price-performance ratio. There is also good drive rigidity with the same accuracy and a small installation space. And there are no high maintenance requirements. “These components are continually being further developed. Looking to the future, the choice of the rack and pinion drive wasn’t a hard one for us,” says Kunzelmann. The conversion from spindle drives to rack and pinion gearboxes went smoothly.

Even more power density

STOBER also delivered right-angle planetary and right-angle servo gearboxes for the thread cutting device. The drive specialist now offers its right-angle servo gearbox in one-stage and two-stage designs. The redesigned series features robust bearing technology and high-quality gearing, which makes it extremely resilient and tip-resistant. Compared to the two-stage variant, the one-stage version with gear ratios of 2 or 4 also enables significantly higher speeds at the output. In the three-stage design, a gear ratio range up to 400 is available.

“Thanks to the space-saving drive, we benefit from a lower weight, high torque and, as a result, increased power density,” says Kunzelmann. Depending on the application and customer options, the components sometimes work together synchronously and sometimes individually. “We designed the drive solutions together with BOSCHERT and Schneider Electric, which supplied the servo drives with the controllers,” Schmidt says. BOSCHERT carried out the commissioning itself.

“We are very satisfied with the entire package,” says Kunzelmann. “With the higher final velocities and dynamics of the drives in particular, our punching machines are much more competitive.” These advantages are due in part to the higher rigidity and precision of the rack and pinion drive. He is also impressed by the collaboration. He said it is “flawless”, support is at the highest level and delivery was made in no time. If there are any problems, BOSCHERT immediately receives straightforward help. It simply works – whether dealing with new projects, challenges or optimizations.

“We delivered our precision gear racks with twice the number of bores. There is a bore for a screw connection every 62.5 millimeters, instead of every 125 as usual. The ZR series features large, helical pinions with a bolt circle. This enables high feed velocities. This enables high feed velocities.”

– Alexander Schmidt, Area Sales Manager at STOBER

This might also interest you

6th Generation Drive Controllers

Tailor-made for any kind of drive task – with four mutually combinable SC6, SI6, SD6 and SB6 series, STOBER always has the right controller on hand.